- We believe that every waste material contains unlimited possibilities—— Vanndai Environmental

- Email:vanndai@vanndai.com

Plastic Shredders: Transforming Waste into Processable Fragments

- Category: Product Center, Scrap metal, Scrap wood, Shredder, Waste building materials, Waste paper, Waste plastic

- |

- Date: 2025年7月21日

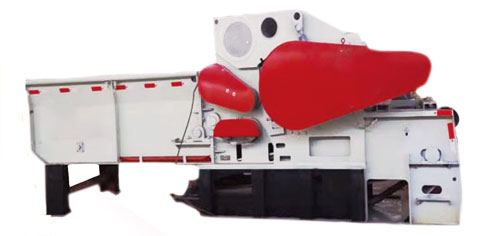

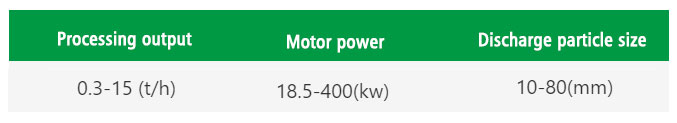

The multi-functional shredder is suitable for crushing various types of plastics in the recycled plastic industry, including hard and soft plastics. It is quiet. High efficiency, environmentally friendly and energy-saving.

Product Details

Plastic shredders serve as the cornerstone of plastic recycling and processing, responsible for breaking down bulky waste—from beverage bottles and industrial containers to complex packaging—into smaller, process-ready pieces. This fundamental step streamlines subsequent recycling stages, enhances material recovery efficiency, and acts as a key component of sustainable waste management.

How Plastic Shredders Work

Most shredders are equipped with one or more rotating shafts fitted with sharp blades, which slice, tear, and crush plastics as they enter the chamber. The size of the output depends on the design: dual-shaft models, with counter-rotating shafts, handle rigid, bulky items like PVC pipes or automotive parts, while single-shaft shredders excel with softer materials such as plastic films or small-scale waste. This mechanical breakdown transforms unwieldy plastics into uniform flakes or chunks—ranging from fine particles to larger fragments—shaped by the shredder’s specific setup.

Versatile Roles in Recycling

Recycling facilities rely on shredders to prepare waste for melting and remolding, while manufacturers use them to recycle in-house scraps, reducing disposal costs and decreasing dependence on virgin materials. While some shredders can handle mixed plastics, sorting beforehand yields the best results—especially for composites or items with metal parts. This adaptability makes shredders essential across sectors, from municipal waste management to specialized e-waste recycling.

Key Benefits of Plastic Shredding

Shredding significantly reduces plastic volume, lowering transport and storage costs. Shredded plastic also melts more quickly during recycling, cutting energy use by up to 30%. By smoothing the recycling workflow and reducing environmental impact, shredders play a crucial role in advancing circular economy practices—proving that effective material transformation is central to sustainable plastic management.

Applicable Plastics for VANNDAI Plastic Multi-functional Shredder

Rigid Plastics: PET (beverage bottles), HDPE/LDPE (detergent bottles, buckets), PVC (pipes, window frames), PP (automotive parts, appliance casings)

Specialized Waste: Industrial scrap (injection molding rejects), post-consumer waste (disposable cutlery), e-waste components (computer shells, TV casings)

Flexible & Soft Plastics: Films (shopping bags, agricultural wraps), elastomers (rubberized seals, hoses), foam plastics (EPS packaging, insulation)

Composite & Engineered Plastics: Plastic-metal hybrids (coated wires, electronics casings), engineering polymers (ABS from car parts, PC from optical discs)

VANNDAI’s multi-functional shredder, designed to handle both pure and mixed plastic streams, integrates seamlessly with recycling plants, manufacturing lines, and waste facilities—maximizing plastic recovery while adapting to diverse materials.

vanndai

We are VANNDAI Environmental Protection Equipment Co., LTD., mainly providing crushing and recycling solutions and equipment manufacturing and sales for waste plastics, waste metals, waste electronic products, waste paper, biomass, etc. Feel free to contact vanndai@vanndai.com

站内搜索

菜单演示

© 2025. All Rights Reserved. Theme By XinTheme