- We believe that every waste material contains unlimited possibilities—— Vanndai Environmental

- Email:vanndai@vanndai.com

Dual-shaft Dual-motor Shredders: Merging Power and Precision in Material Handling

- Category: Product Center, Scrap metal, Scrap wood, Shredder, Waste building materials, Waste paper, Waste plastic

- |

- Date: 2025年7月21日

The double-electric series is a heavy-duty shear crusher. This series of products is equipped with dual-motor drive, featuring strong power and stable structure, making it a powerful tool for handling various solid wastes. The domestic high-alloy wear-resistant cutting tools, 40Cr transmission shafts, and detachable fixed tools reduce the maintenance costs for customers in the later stage.

Product Details

In plastic recycling and material processing, the double-shaft double-motor shredder emerges as an engineering standout, blending raw power with precise control. Unlike single-shaft alternatives, this advanced equipment features two independent motors that drive counter-rotating shafts—a design that takes heavy-duty material reduction to unprecedented levels.

At its core, the shredder relies on two interlocking blade shafts spinning in opposite directions, generating intense shearing force within the chamber. The dual motors deliver the torque required to tackle tough materials: industrial plastic drums, large-format sheets, and thick-walled pipes are torn down with seamless efficiency. Their synchronized rotation continuously pulls materials into the machine, eliminating jams and ensuring uninterrupted operation. Precision is built into every component: adjustable blade angles and spacing allow operators to fine-tune motor speed and gap sizes, producing everything from fine plastic flakes (ideal for granulation) to uniform chunks (perfect for specialized recycling) with impressive consistency.

This shredder’s versatility makes it a linchpin across industries. In large recycling facilities, it handles mixed plastic waste streams, reducing volume to simplify sorting, cleaning, and reprocessing. Manufacturers use it to recycle in-house scraps—shredding defective products and off-cuts for immediate reuse in production lines—lowering raw material costs and minimizing landfill waste. Beyond plastics, it manages rubber waste, e-waste with plastic parts, and even wood-metal composites, solidifying its role as a cornerstone for businesses focused on waste optimization and circular economy practices.

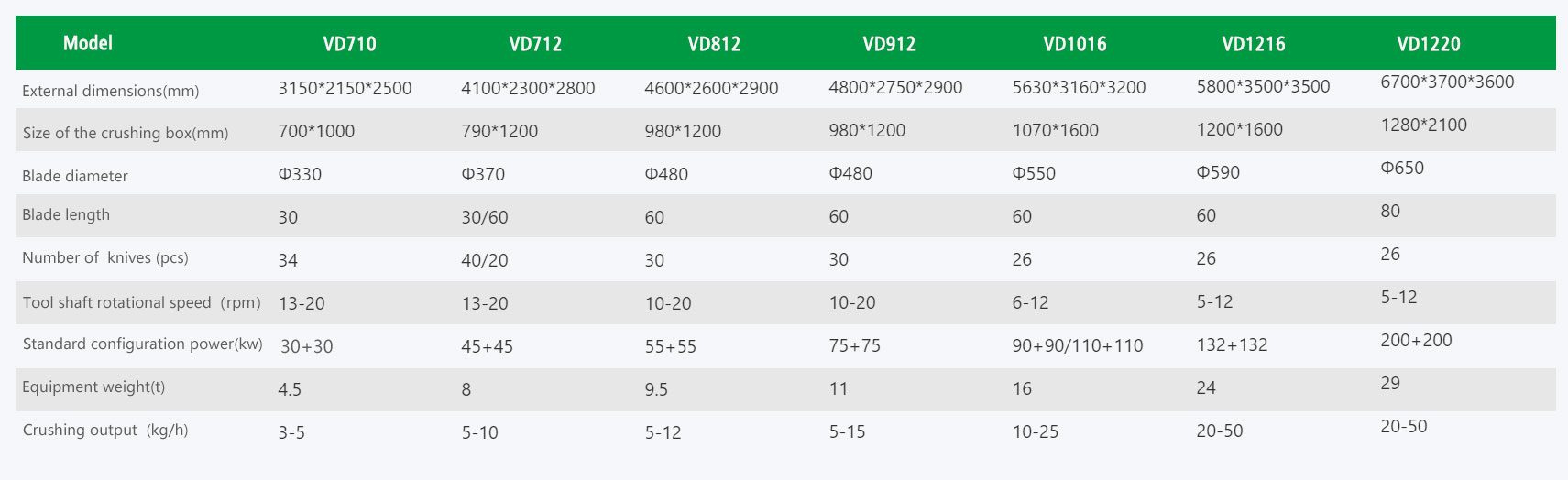

The parameters of the dual-shaft dual-motor shredder are as follows

As a gold standard in shredding technology, the double-shaft double-motor shredder redefines material processing by combining unmatched power with precise control. It’s a testament to the idea that sustainable recycling requires both brute force and technical refinement—and as global demand for efficient waste solutions grows, this machine will remain a driving force in shaping the future of resource recovery and circular manufacturing.

vanndai

We are VANNDAI Environmental Protection Equipment Co., LTD., mainly providing crushing and recycling solutions and equipment manufacturing and sales for waste plastics, waste metals, waste electronic products, waste paper, biomass, etc. Feel free to contact vanndai@vanndai.com

相关推荐

站内搜索

菜单演示

© 2025. All Rights Reserved. Theme By XinTheme